We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Battery & Charger Storage

Forklift batteries and chargers are two of the most important investments in any material handling system. Preserve these essential assets with Battery & Charger Storage solutions from BHS, Inc.

Since 1979, BHS, Inc. has been engineering and manufacturing forklift battery stands that provide measurable throughput improvements by protecting equipment; improving battery room safety; and ensuring efficient change-outs with every shift.

We offer battery room infrastructure for every size and type of electric fleet, whether you access batteries vertically or through a side panel. Keep reading to explore the options, or call the BHS sales team at 1.800.BHS.9500 for personalized guidance.

Battery & Charger Storage Equipment Selection Guide

Side Extraction Battery Stands

In a side-extraction application, batteries slide horizontally from trucks into stands (and vice versa). Choose from these battery stands with a roller-lined base.

Safely store and charge any number of forklift batteries in System Stands between one and four levels high.

Charge, store, and change out forklift batteries in free-standing units.

Provide 360-degree access to forklift batteries during maintenance tasks.

Change forklift batteries faster with a track mounted battery stand that moves to line up with lift truck panels. Stores one charged battery and one discharged battery.

Vertical Extraction Battery Stands

Overhead battery systems lift batteries with Gantry Cranes, storing them in stands with tough and stable decking.

Recycled polyethylene decking and a powder-coated steel frame provides acid-resistant, nonconductive storage for forklift batteries in Gantry Crane systems.

Charger Stands and System Accessories

Complete the ideal battery room with Charger Stands, Cable Management tools, and Drip Pan kits that safely keep electrolyte contained. These tools serve both side-extraction and overhead battery changing operations.

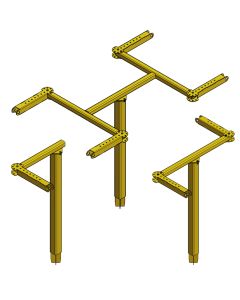

Protect battery chargers by storing them on elevated steel Charger Stands — or on walls with Charger Wall Brackets. Ideal for traditional battery rooms or fast/opportunity charge applications.

Contain electrolyte drips and boil-overs with integrated steel Drip Pans, complete with acid-neutralizing inserts.

Cable Retractors, Reels, and Magnetic Mounts keep charging cables safely out of lift truck travel paths, while providing convenient access during charges.

Protect Forklift Batteries and Chargers With a Limited Footprint

Safety standards from the Occupational Safety and Health Administration (OSHA) require employers to provide secure battery and charger storage.

- In general industry operations like warehousing and manufacturing plants, OSHA standard 1910.178(g)(2) requires facilities to protect “charging apparatus from damage by trucks.”

- In the construction industry, OSHA standard 1926.441(b)(2) imposes the same requirement, while standard 1926.441(a)(3) states that battery “racks and trays shall be substantial and shall be treated to make them resistant to electrolyte.”

- Standard 1910.178(g)(11) requires employers to take precautions that “prevent open flames, sparks, or electric arcs in battery charging areas.”

Forklift battery and charger stands from BHS, Inc. comply with these and other regulations through smart engineering. All stands feature heavy duty steel construction with an acid-resistant powder-coat finish. Both roller beds and static polyethylene decking are spark-proof and resistant to electrolyte. Drip Pan Kits with acid-neutralizing pillows collect any excess electrolyte and render it inert to protect employees, floors, and other infrastructure.

In addition to improving battery room safety, these units are designed to take full advantage of vertical space. That limits the size of battery handling areas, leaving more square footage for revenue-generating tasks.

The battery handling experts at BHS, Inc. can help you optimize forklift battery infrastructure, from storage solutions to extraction plans, from the ground up. That leads to measurable improvements in safety, efficiency, and facility throughput.

Contact BHS at 1.800.BHS.9500 to discuss your unique battery handling needs, and find solutions that deliver strong positive results.