We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Industrial Internet of Things (IIoT) Solutions from BHS

The Industrial Internet of Things, or IIoT, is part of the digital transformation taking place among manufacturers, distributors, supply chain operators, and more. But what exactly are we talking about when we discuss the Industrial IoT? There are about as many definitions of the term as there are purveyors of smart machinery.

We’ll keep it simple. In order to obtain the advantages associated with IIoT, users need three components:

Smart Sensors

Smart sensors embedded in industrial assets. These sensors collect and transmit real-time data through cloud technology, monitoring equipment condition, usage statistics, operator information, inventory, and more.

IIoT Analytics Software

IIoT analytics software that can process sensor data into actionable insights. Ideally this is an entire software environment tied in with the user’s broader ERP.

Users

That is, people. Software can generate intelligence, but only people can take that intelligence and translate it into measurable efficiency gains. Operators interact with connected equipment through a human-machine interface, or HMI.

The Industrial Internet of Things itself is the network that incorporates these three elements. The competitive advantages that IIoT can provide require a customized, streamlined approach built for each individual environment.

Here’s how BHS, Inc. can help forklift users, material handling operators, and electrical supply distributors obtain the benefits of IIoT functionality. These benefits improve safety, operational efficiency, and, ultimately, the bottom line. Keep reading for information on BHS IIoT solutions and links to our custom IIoT mobile portals. If you have any questions, call us at 1.800.BHS.9500.

BHS IIoT Solutions in the Forklift Battery Room

Battery usage has a huge impact on the cost of running an electric forklift fleet. Without a data-driven fleet management strategy, 30 percent of forklift batteries end up underused. The use of IIoT Fleet Management Systems can boost average operating time of up to 30 minutes per battery per charge. Click here to learn about why forklift battery rotation management is important.

BHS, Inc. provides software, hardware, and smart battery handling equipment to create an entire enclosed digital environment that can extend the working life of every battery in the fleet.

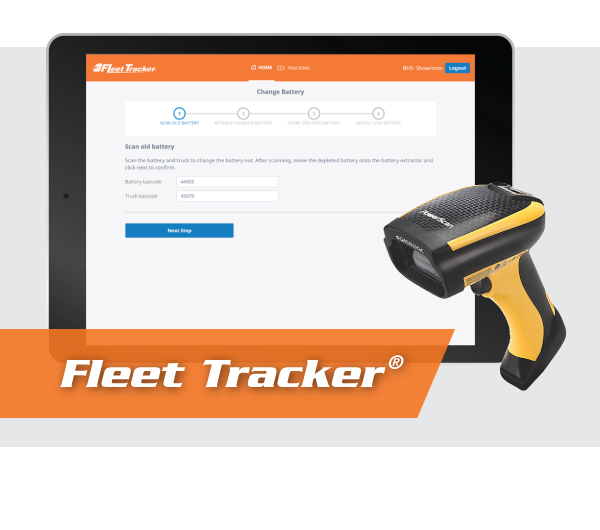

![]() BHS Fleet Tracker® (FLT-IIOT) is a cloud-based fleet-management system, with detailed reporting that allows users to right-size their fleets for optimal efficiency. Connection to the IIoT allows managers to measure the health of batteries, stands, and trucks by logging into a secured Web Portal.

BHS Fleet Tracker® (FLT-IIOT) is a cloud-based fleet-management system, with detailed reporting that allows users to right-size their fleets for optimal efficiency. Connection to the IIoT allows managers to measure the health of batteries, stands, and trucks by logging into a secured Web Portal.

Fleet Tracker’s touchscreen HMI mounted on battery extractors guides users to charged batteries, posts maintenance reminders, and updates the status of battery assets to the cloud. The Fleet Tracker system improves battery health, improves change-out efficiency, and gives managers the real-time data they need to eliminate waste by matching assets to needs exactly.

BE-MAX, the IIoT-Integration on BHS Operator Aboard Battery Extractors makes for a fully connected battery change-out machine for high-volume users. In addition to the efficiency and safety benefits already associated with BHS BE models, the the IIoT-enabled unit provides telematics capabilities to capture and transmit key data points.

Smart sensors located throughout the system send push notifications when the unit is off-level or when oil begins to degrade. Sensors transmit data in real time, allowing users to employ a condition-based or predictive maintenance strategy. Compared to maintenance schedules, these models reduce unscheduled downtime and boost overall uptime by addressing maintenance needs as they actually arise, but before adverse conditions can cause harm.

BE-MAX only allows authorized users to log in through the touch screen HMI located on the unit. The system tracks usage and productivity across every shift. And it ships with a subscription to the manager's web portal, a dashboard managers can access from virtually any internet-connected computer or mobile device. This portal gives managers access to detailed operational data and analytics. By generating detailed reports using this data, company leadership can make more informed decisions on everything from staffing levels to productivity goals.

Users setup with a login can click here to access the BE-MAX remote-access portal. For more information on how BHS products can reduce the cost of ownership for electric forklifts, call our sales team at 1.800.BHS.9500.

BHS IIoT Solutions in Material Handling

To learn more about Material Handling Equipment from BHS, click here. To discuss custom material handling solutions, including connected equipment compatible with IIoT ecosystems, call our sales team at 1.800.BHS.9500.